Ensuring Safety and Quality: Outdoor Porcelain Tiles for Sale and the Manufacturing Process

Introduction

In the world of construction and design, outdoor porcelain tiles have gained immense popularity due to their durability, versatility, and aesthetic appeal. However, when it comes to purchasing porcelain tiles, concerns about safety and quality often arise, particularly when considering products from China. In this blog post, we will explore the manufacturing process of porcelain tiles and address the safety concerns associated with porcelain tiles from China.

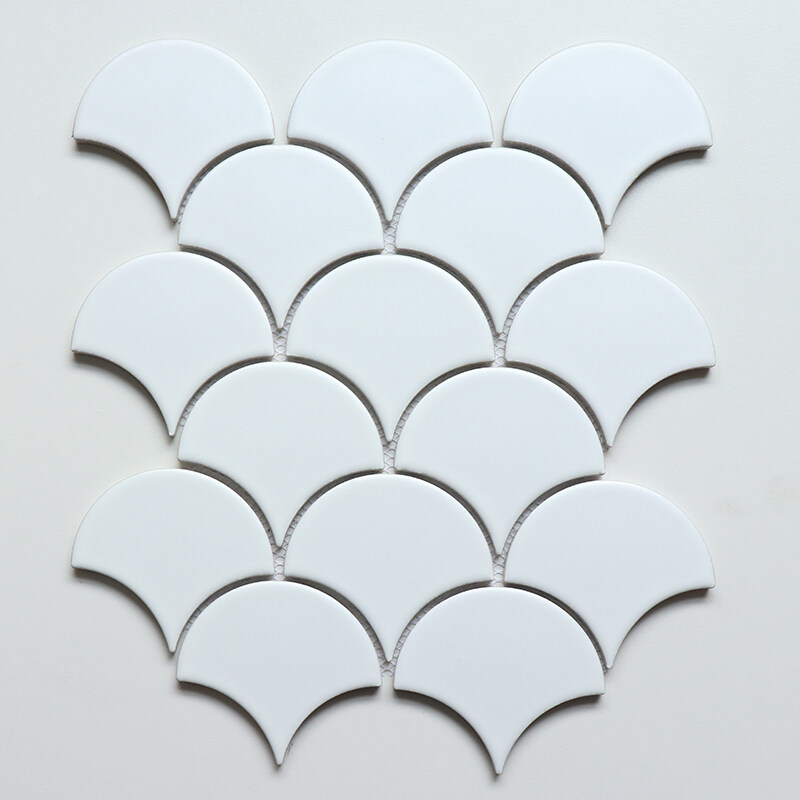

Understanding Outdoor Porcelain Tiles

Outdoor porcelain tiles are specifically designed to withstand harsh weather conditions, making them an ideal choice for outdoor spaces such as patios, gardens, and walkways. These tiles are made from a mixture of clay, sand, and other natural materials, which are then fired at high temperatures to create a dense and durable product.

The Manufacturing Process of Porcelain Tiles

The manufacturing process of porcelain tiles involves several stages, ensuring the final product’s quality and safety. Here is a brief overview of the process:

a. Raw Material Preparation:

The first step involves selecting high-quality raw materials, including clay, feldspar, silica, and other minerals. These materials are carefully measured and mixed to create a homogeneous blend.

b. Shaping and drying:

The blended mixture is then shaped into tiles using various techniques, such as extrusion or pressing. The tiles are then left to dry naturally or in a controlled environment to remove excess moisture.

c. Firing:

The dried tiles are placed in kilns and fired at extremely high temperatures, typically ranging from 1200 to 1400 degrees Celsius. This firing process ensures the tiles’ strength, durability, and resistance to water absorption.

d. Glazing (optional):

Some porcelain tiles undergo a glazing process to enhance their appearance and provide additional protection against stains and scratches. Glazing involves applying a layer of liquid glass to the surface of the tile, which is then fused during the firing process.

e. Quality Control and Testing:

Throughout the manufacturing process, strict quality control measures are implemented to ensure that the tiles meet industry standards. This includes testing for water absorption, strength, slip resistance, and other performance characteristics.

Safety Concerns: Porcelain Tiles from China

When considering porcelain tiles from China, it is essential to address safety concerns. While it is unfair to generalise the safety of all Chinese porcelain tiles, it is crucial to conduct due diligence and work with reputable suppliers. Here are a few factors to consider:

- Certifications and Standards:

Ensure that the porcelain tiles meet international standards and certifications, such as ISO 13006 or ANSI A137.1. These certifications guarantee that the tiles have undergone rigorous testing and comply with safety regulations.

b. Supplier Reputation:

Research the reputation and track record of the supplier. Look for reviews, testimonials, and certifications that demonstrate their commitment to quality and safety.

c. Independent Testing:

Consider conducting independent testing of the porcelain tiles to verify their safety and quality. This can provide peace of mind and assurance that the tiles meet your specific requirements.

Conclusion

Outdoor porcelain tiles offer an excellent solution for enhancing outdoor spaces, providing durability and aesthetic appeal. By understanding the manufacturing process and addressing safety concerns associated with porcelain tiles from China, businesses can confidently select high-quality products for their projects. Remember to prioritise certifications, supplier reputation, and independent testing to ensure the safety and quality of the porcelain tiles you choose.